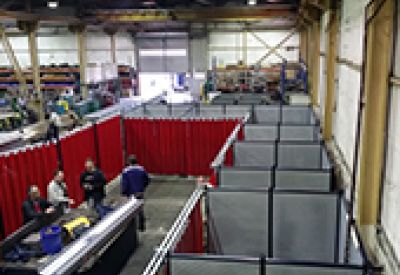

Welding workplace at ThyssenKrupp Millsystems in Oberhause equipped with Cepro!

- Fixed cabins for all welding trainees and welders.

- Whole welding area conforming to most actual safety standards.

With the new welding cabins all employees have a safe workplace to work without being subjected to welding light, sparks and noise produced by their co-workers. The other employees which work in the surrounding of the welding area can now also work in an safer environment, with no harmful radiation and welding light reaching them.

Companies with smaller workplaces can still benefit enormously from a new equipped welding area. Because of the noise and reflection reducing properties of our Sonic wall elements the effects which noise has on the human body are greatly reduced, resulting in employees who will be more energetic and better concentrated, while sickness levels will be reduced.

Would you like to optimize you workplace and have it conform to the most actual safety standard, then contact us right away and we will get started.